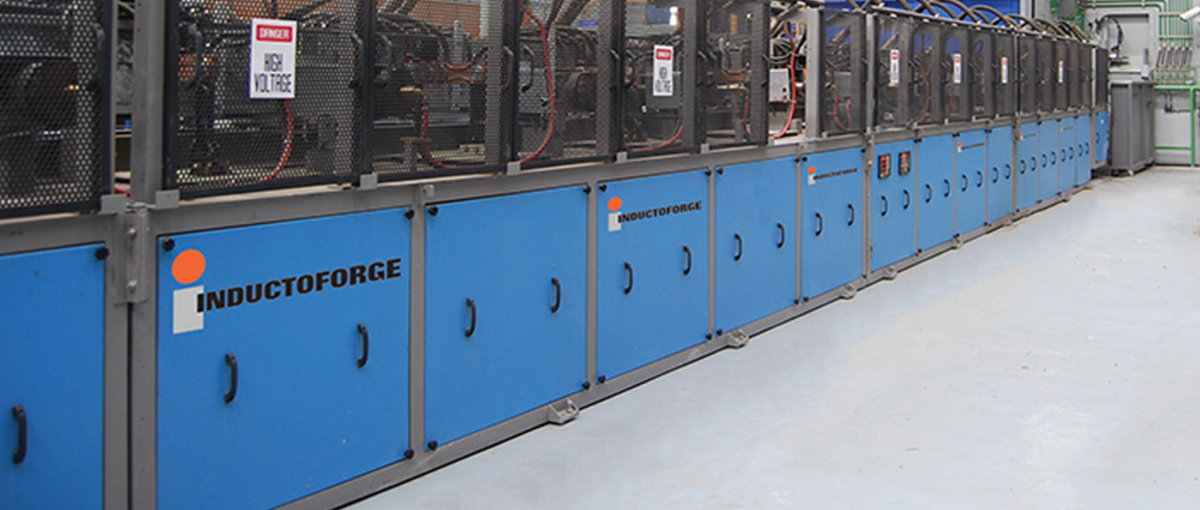

Inductoforge® Induction Bar Heating Systems for Forging

During the last 40 years, induction heating has proven to be a viable and effective solution for billet and bar heating for the forging industry. Induction forging allows for the heating of a billet’s while providing reduced scale, faster start-up, and is much easier to automate than other methods of heating.

The inductoforge® brand of induction heating systems combine the flexibility of modular technology and the advanced control capability of iHAZTM (our proprietary numerical simulation software engine) to deliver the best possible temperature uniformity at the highest production rates. These systems utilize individually controlled and extremely efficient power supplies to process more lbs. per hour using less energy compared to conventional forging systems.