Computer Simulation for Induction Heating

Computer simulation for induction heating is a powerful tool that enables engineers and scientists to investigate or design a physical system and/or process using a virtual mathematical model. The vast majority of modern computer simulation software packages utilize numerical methods (e.g. finite element method or “FEM”) to evaluate extremely complex physical systems – systems that are otherwise impossible to precisely analyze. By leveraging the power of modern computer hardware, simulation software can provide substantial improvements in the efficiency, reliability, and cost-effectiveness in design and development processes.

Why is induction heating computer simulation so valuable in designing induction heating systems and processes?

From a design perspective, computer simulation is valuable for a number of reasons – two of the most notable being:

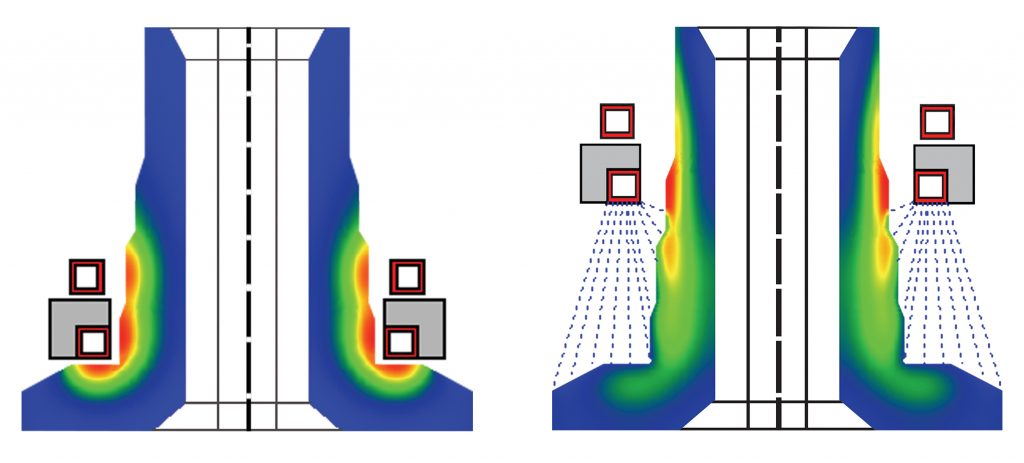

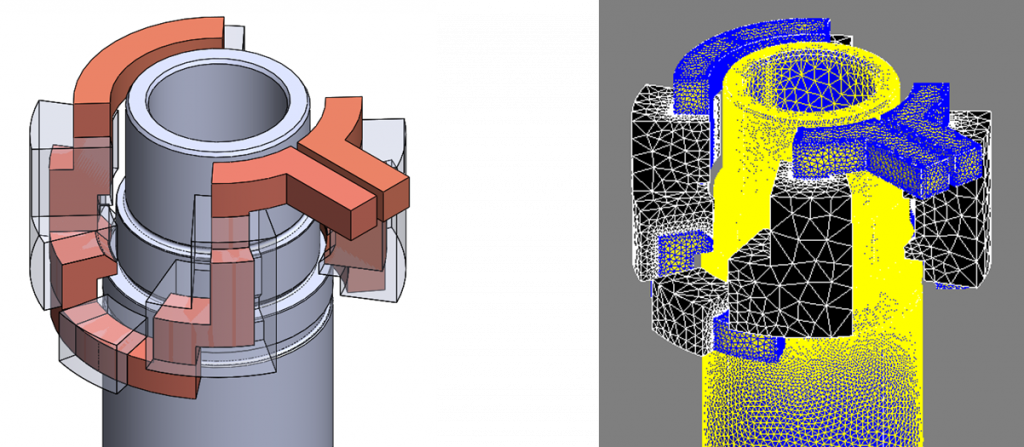

- The physics involved in utilizing electromagnetic induction as a deliberate and controlled source of heat generation is extensive and multi-faceted. Computer simulation provides a quantitative approach to designing and developing induction heating processes, allowing complex physical phenomena that cannot be physically observed and/or measured to be clearly visualized and quantified.

- Because electromagnetic induction offers an extremely effective, economical, and versatile means of heating conductive materials, the scope of induction heating applications is very broad. This includes (but is not limited to):

- Heat treatment (hardening, tempering, normalizing, stress relieving)

- Forming (hot/warm forging, rolling, stamping)

- Joining (welding, brazing, soldering, bonding, shrink fitting)

- Other (curing, coating, crystal growing)

Furthermore, each of these general applications includes countless different workpiece types, geometries, materials, and heating requirements. As a result, no “universal solution” exists in the design of induction heating equipment. Induction heating computer simulation offers the most efficient means of developing customized and optimized solutions and is, therefore, a necessity – not a luxury – in the modern induction heating industry.

How does computer simulation provide benefits to our customers?

The use of induction heating computer simulation software can promote substantial improvements in the performance and cost-effectiveness of induction heating equipment, in addition to large reductions in the cost and time required to design and develop induction heating processes. Due to the significant increase in design and development efficiency, the use of computer simulation allows Inductoheat to:

- Deliver equipment and process designs that meet/exceed quality requirements and provide optimal performance and efficiency

- Improve process robustness by predicting and accounting for deviations inherently encountered in real-life life production environments

- Substantially reduce engineering and process development costs by “shortening the learning curve”

- Evaluate process feasibility in a quick, reliable, and cost-effective manner

- Conduct 3rd party equipment performance assessments and offer informed suggestions for improvement

- Provide innovative equipment and processes to our customers by considering a comprehensive array of potential induction heating solutions

What makes Inductoheat the world-recognized leader in computer simulation?

Maximizing the aforementioned benefits of computer simulation requires intellectual understanding of the physics of induction heating (and related subjects) and know-how in applying computer simulation results to real systems and processes.

Inductoheat has long been considered the global pioneer in the development and implementation of computer simulation in the induction heating industry, as illustrated by our exclusive invitations (by publishers such as ASM International, Marcel Dekker, CRC Press, Elsevier, etc.) to discuss this subject matter in many internationally renowned journals and handbooks. Our unparalleled practical experience and expertise; access to leading proprietary and commercial software; and support from the Inductotherm Group – the largest induction heating organization in the world – give Inductoheat an undisputed advantage over the competition.

Whom should I contact regarding potential computer simulation work?

You can contact any one of our territory representatives or click the “Request a Quote” button below.

Request a Quote